Magneto-active composites with locally tailored stiffness produced by laser powder bed fusion

New publication

2023/12/08

K. Schäfer, M. Lutzi, M. Bilal Khan, L. Schäfer, I. Dirba, S. Bruns, I. Valizadeh, O. Weeger, C. Hartmann, M. Kupnik, E. Adabifiroozjaei, L. Molina-Luna, K. Skokov, O. Gutfleisch

Additive Manufacturing, 79, 103905 (2024).

DOI: 10.1016/j.addma.2023.103905

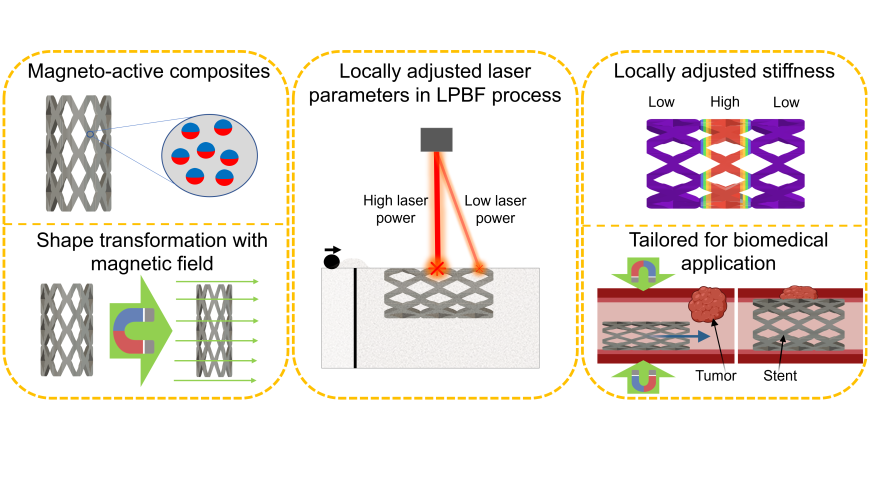

Additive manufacturing technologies enable the production of complex and bioinspired shapes using magneto-responsive materials, which find diverse applications in soft robotics. Particularly, the development of composites with controlled gradients in mechanical properties offers new prospects for advancements in magneto-active materials. However, achieving such composites with gradients typically involves complex multi-material printing procedures. In this study, a single-step laser powder bed fusion (LPBF) process is proposed that enables precise local adjustments of the mechanical stiffness within magneto-active composites. By utilizing distinct laser parameters in specific regions of a composite containing thermoplastic polyurethane and atomized magnetic powder derived from hard magnetic Nd-Fe-B, the stiffness of the composite can be modified within the range of 2–22 MPa. Various magneto-responsive actuators with locally tailored stiffness are fabricated and their magnetic performance is investigated. The enhanced response exhibited by actuators with locally adjusted mechanical properties in comparison to their homogeneous counterparts with identical geometries is shown. As a demonstration of a biomedical application, a magnetically responsive stent with localized adjustment is presented with the ability to meet specific requirements in terms of geometry and local stiffness based on an individual's anatomy and disease condition. The proposed method presents an approach for creating functionally graded materials using LPBF, not only for magneto-active materials but also for several other structural and functional materials.