Cellular precipitation in Ni-Mn-Sn revealed

New publication

2024/01/17

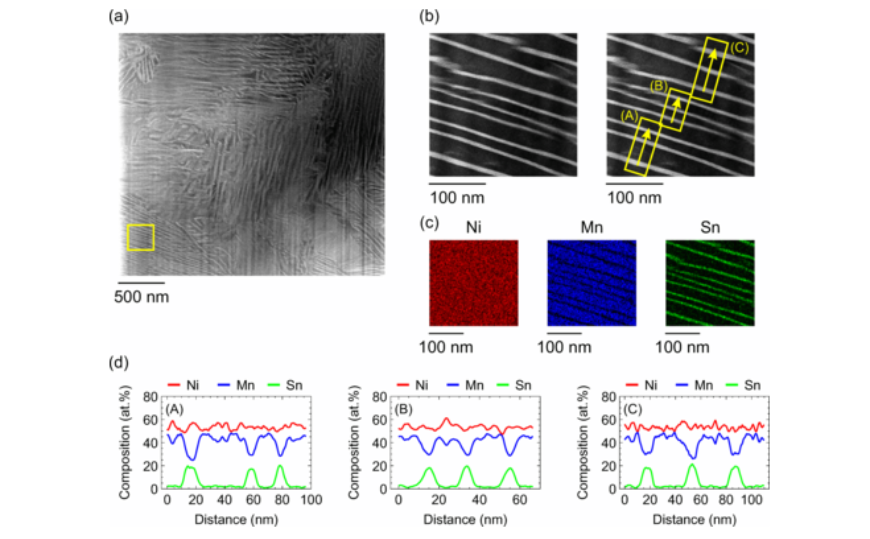

Combining the expertise from 5 participating projects the location and morphology of ferromagnetic precipitates in Ni-Mn-Sn was determined. Ni50Mn45Sn05 heated above 600 K decomposes into ferromagnetic Ni2MnSn precipitates in an antiferromagnetic NiMn matrix. If an external magnetic field is applied during annealing, magnetic hysteresis curves with high coercive fields of up to 5 T can be achieved. The origin of this hysteresis has been attributed to the coupling of the antiferromagnetic matrix L10 NiMn with ferromagnetic precipitates (Sn enriched regions), whose location and morphology were not known. To close this knowledge gap, a range of sophisticated experimental techniques – ranging from magnetic force microscopy over transmission electron microscopy to atom probe tomography -was applied aside from conventional magnetometry and x-ray diffraction. The decomposition type is identified as a cellular precipitation starting at grain boundaries and growing into the grains. This leads to a multilayer thin film like lamellar structure with a lamella thickness in the nm range as seen in the attached figure. These results may provide a basis for understanding the magnetic interactions, which lead to the magnetic hysteresis with ultra high coercivity in these types of “shell ferromagnets”.

N. Josten, S. Franzka, Z. Rao, T. Smoliarova, A. Kovács, F. Scheibel, F. Staab, M. Acet, A. Çakır, K. Durst, B. Gault, R. E. Dunin-Borkowski, O. Gutfleisch, M. Farle

Phys. Rev. Materials 7, 124411 (2023).

DOI: 10.1103/PhysRevMaterials.7.124411