Overview

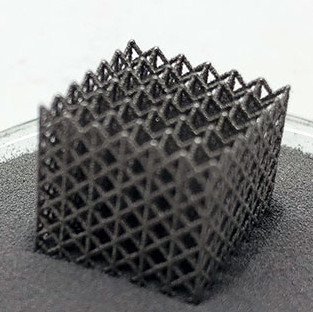

AM will be used to alter the microstructure of Ni-Mn-X with X = In, Sn (or Ga, Al), to increase its mechanical stability to prevent intergranular cracking due the anisotropic volume change during phase transformation and selectively adjust its ferromagnetic transformation range and thermal hysteresis. This will be achieved by modifying the composition of the alloy to adjust the Curie temperature and the martensitic transformation temperature. This project will strongly collaborate with the additive manufacturing projects B11, A10, A11, A06, B13, benefit from characterization by B01, B04, A12, A08 and the machine learning project B12.

The focus will be placed on compositionally complex alloys (CCA) nanoparticles (NPs) dispersed in an organic solution. Properties of CCA NPs and their formulation in an ink are widely unknown areas, since – until now – the controlled synthesis of colloidal CCA NPs with targeted elemental composition was not demonstrated. In this project, pulsed laser ablation in liquids (PLAL) of well-characterized compositionally complex alloy targets consisting of five elements, e.g. CrFeCoNiX (X = Mn, Cu), will be carried out in defined liquid-based media to synthesise magnetocaloric quinary transition metal alloy nanoparticles.

Team

| Name | Contact | |

|---|---|---|

| Univ.-Prof. Dr. Bilal Gökce | goekce@uni-wuppertal.de +49 (0) 202 439 - 5340 |

| Hamed Shokri | shokri@uni-wuppertal.de +49 (0) 202 439-5390 W.11 073 |

| M.Sc. Shabbir Tahir | tahir@uni-wuppertal.de |

| Inna Yusnila Khairani | Khairani@uni-wuppertal.de +49 (0) 202 439 5391 |