In project B1, we develop the fundamental knowledge landscape to use these motors to design and optimize a transient sieve. For that purpose, we closely collaborate with project A2, where such a sieve is realized experimentally.

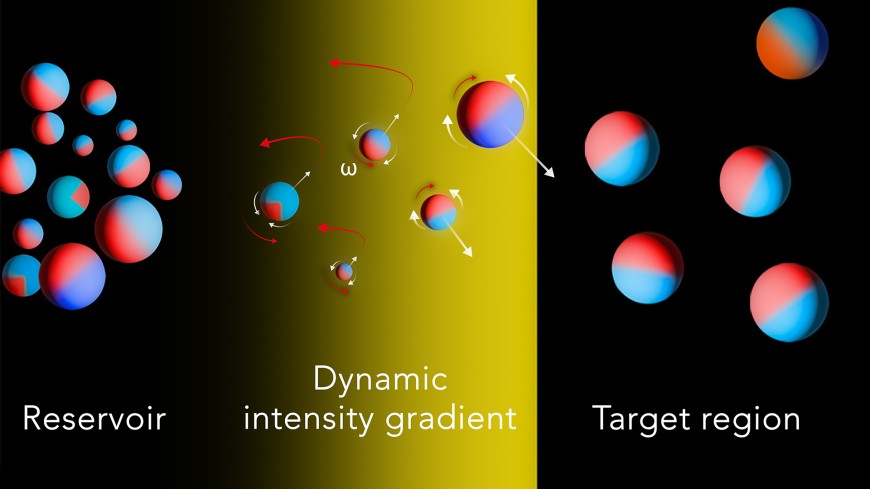

To design a transient sieve for colloidal motors, and later also for cargo particles, we exploit the fact that the dynamics of colloidal motors can be directed by spatiotemporally modulated light fields (laser). This can be used to construct a transient sieve for Janus motors, based on light barriers which can be dynamically opened and closed in such a manner that the motors can pass the light barrier selectively, depending, e.g., on their size, surface morphology or on the type of cargo particles attached to them. In B1 we span the entire range from the development of a detailed model describing the coupled dynamics of colloidal motors, the ambient flow field and the temperature field to an effective model to describe the spatiotemporal dynamics of the motors and cargo particles.

Team

| Name | Contact | |

|---|---|---|

| Prof. Dr. Benno Liebchen | benno.liebchen@pkm.tu-... +49 6151 16-24509 S2|04 104 |

| Dennis Schorn M.Sc. | dennis.schorn@pkm.tu-... +49 6151 16-24579 S2|04 301 |