Motivation and Objectives of Subproject 5

In order to apply materials in new fields of application, a wide range of tests are necessary, both in terms of the fundamental feasibility, as well as for reasons of optimization. Numerical simulations can be used to minimize the scope of necessary tests. The aim of “building with paper” offers a wide range of approaches for such simulations. On the one hand, components and groups can be subjected to different stress conditions, which can often only be carried out with great effort in a laboratory test. On the other hand, an improvement in the co-operation of different paper and other materials can be obtained e.g. At connection points. A corresponding material model is developed as the basis for this, which adequately describes the properties of the paper material. The modelling of the material behavior must take into account the relevant influencing parameters for the project.

The characteristic properties of paper materials make it necessary to pursue existing approaches for the description of the material behaviour and, if necessary, to expand them. In particular, the temporal behavior (viscosity) as well as the influence of temperature and humidity play a decisive role. The viscoelastic and viscoplastic behavior has been given great attention in recent years in connection with material models. However, a final formulation of a model, which takes all the aspects mentioned into consideration, is still a primary objective of the subproject. The focus is on practical applicability with regard to the project objective. For example, it is important to predict the onset of damage as a result of delamination phenomena with justifiable computational complexity in relation to the desired structural and overall structural simulations. Since on the industrial side, hardly favourable mass products have been produced on the topic of building with paper, the integration of the simulation at an early stage in the development cycle is of high relevance.

Material development and modeling

In TP 5, characterization tests are carried out on starting materials for semifinished products as well as component tests. Thus, the relevant characteristic data of the paper materials can be determined and their change as a result of the production of the components can be examined. Furthermore, the component tests are used to validate the material models in question.

Simulation and modelling of adhesive joints

Parallel to the material characterization, samples are taken from adhesive joints and tested. The strength and the duration behavior modified by the bonding can thus be examined in detail and used in the structure simulation as well as for further optimization in coordination with TP1 to TP4.

Validation via component and module tests

Finally, experimental investigations on complex geometries under laboratory conditions are carried out on components and modules. Thus, multi-axial stress states and thus the universal validity of the material model for structural mechanics are also checked.

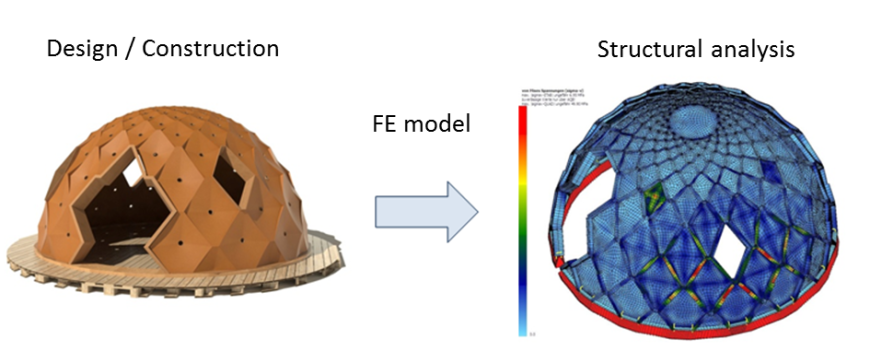

Structural simulation at the demonstrator (overall structure) and at various modules

The simulation is based on the overall structure of the demonstrator building defined in the project as well as on selected modules in coordination with subprojects 6 and 7. The model is constantly modified during the course of the project and finally supplemented by simulations with the validated material model.