CRC – TRR361/F90

Collaborative Research Centre – TRR361/F90: CREATOR – Computational Electric Machine Laboratory

CREATOR

TU Darmstadt, TU Graz and JKU/RICAM, Linz, are intensifying their research into how electrical machines can be decisively improved through computer simulation. To this end, the first German-Austrian Collaborative Research Centre/Transregio – TRR361/F90 has been approved. The German Research Foundation (DFG) and the Austrian Science Fund FWF are funding the TRR “Computational Electrical Machine Laboratory” with a total of over eight million euros.

Vision

Electric machines have played a major role in energy conversion already for decades. Modern power electronics have brought major improvements and together with the advent of new materials and manufacturing techniques unprecedented opportunities for future innovation exist. Backed by advances in design optimisation and control, novel drive systems provide huge potential to further increase energy conversion efficiency, and thereby contributing to meeting climate goals.

While current drive systems are operated in different environments and at variable speeds, current design procedures usually start with an expert’s choice for a particular machine type and topology. Dimensioning is then based on a limited number of parameters and well-chosen operation modes, typically at constant speed or torque. Thereby considerable opportunities for optimisation are missed. Only a paradigm shift towards a fundamentally new integrated simulation and design approach will allow the potential of modern electric drives to be fully exploited. From the outset, this approach must consider all relevant aspects of a machine, e.g. shape and topology, time-dependent operating cycles, complex material behaviour, uncertainties and robustness, new cooling techniques to push thermal limits, noise and vibrations and various key performance indicators. The modelling, simulation and optimisation of such a complex system pose an extreme computational engineering challenge.

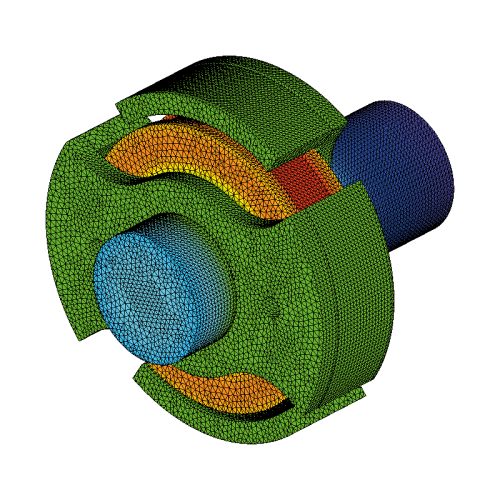

Novel 3D designs for electrical machines

Novel machine designs can be optimised for variable speed capability, variable loading, thermal constraints, energy conversion efficiency and increased demands on reliability, robustness and noise-vibration-harshness performance. To fully unlock the potential of these new technologies and to achieve the challenging motor targets of the future needs a fundamentally new integrated simulation and computer assisted design approach.

This Collaborative Research Centre (CRC) will lay the foundations for the next generation electro-thermal machine design to overcome the challenges of modelling, simulation and optimisation in these multiscale and multiphysical systems. In particular, we address (i) modelling of nonlinear material behaviour, e.g. hysteresis, losses and novel cooling strategies, (ii) simulation of coupled electronic-electromagnetic-mechanical-thermal multiscale dynamical systems, (iii) flexible geometry handling, involving rotating geometry and geometric design, (iv) multiobjective shape and topology optimisation, sensitivity analysis and uncertainty quantification. The innovations in these areas will boost the predictive power of machine models. They will allow design engineers to take full advantage of the recent achievements in the conception of next-generation electric machines.

For this, the CRC is organised in four scientific Project Areas, as well as an area of central projects for research training, research data management and project management. The four scientific areas are classified into electromagnetism, fluid mechanics, numerics and optimisation. All projects are interwoven, with the regular exchange of results, including models and algorithms. Validation is ensured by integrated measurements. The different multiphysical and multiscale aspects are tackled in a holistic approach with a project plan designed to fully address the interdisciplinary character of the task.