Laser view inside the particle

How LIBS makes the composition of iron particles visible

2025/01/27

The atomic composition of the surface of single particles during thermochemical oxidation is supposed to be analyzed non-intrusively and in situ by means of laser-induced breakdown spectroscopy (LIBS). This allows the energy release of the particles to be tracked during the process. Simultaneously to LIBS, the measurement technique Diffuse Backlight Illumination (DBI) is used to investigate the laser-particle interaction and to determine the hit quality and individual hits.

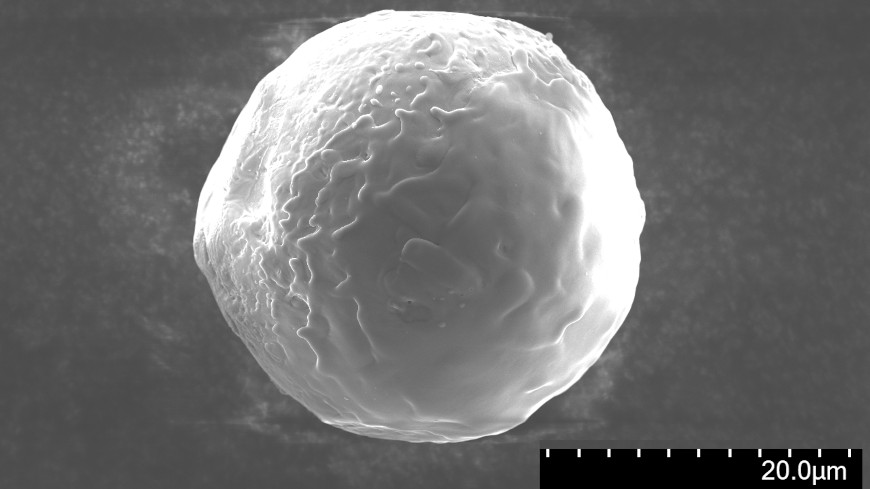

An important parameter for evaluating the LIBS measurement results is the penetration depth of the laser and thus the volume of particles transferred into the plasma. Initial analyses using a confocal microscope revealed a penetration depth of approximately 2 µm in pure iron sheets. To determine the differences between metal sheets and particles, individual particles were captured after laser shot and analyzed under a scanning electron microscope. The image shows the melted particle surface on the right-hand side of the image. This is followed by a transition in which the melt has solidified and the natural surface of the iron particle on the left-hand side of the image. From this it can be shown that the order of magnitude of the penetration depth of sheet metal can also be transferred to particles.