Exergy is the “valuable part” of energy and thus makes a statement about the quality of a form of energy. While energy is a conservation variable that is only converted but never lost, exergy loss always occurs in technical processes. The lower the exergy loss, the better the process. If the exergy losses of the subsystems/processes are determined for complex systems, it can be clearly seen where the system should be improved.

Consideration of costs and technical options

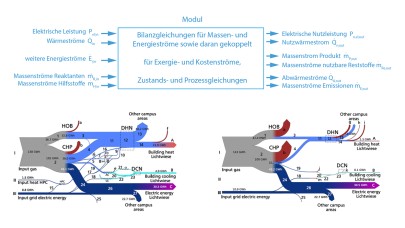

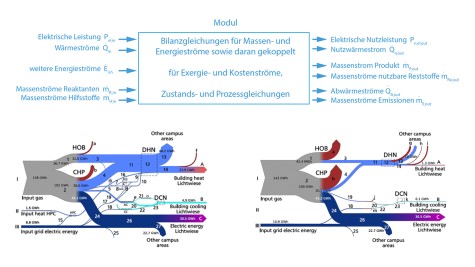

An exergoeconomic analysis combines an exergetic analysis with an economic analysis. It is particularly suitable at an early stage of process development for estimating the cost relations of different technical solution options. For this purpose, specific costs must be assigned to the exergies that are supplied to a system and to the components that make up the system. The result of an exergoeconomic analysis is exergy and cost flows through the system under investigation. As a rule, the product generation costs are then used as the basis for evaluation. In the case of Clean Circles, these are the electricity generation costs. The systems of equations established within the framework of the energy and exergoeconomic analysis also form the basis for optimization.

Scientific challenges:

- Division of Clean Circles into meaningful subsystems with input and output variables as well as model approaches

- Model development and validation of individual modules

- Construction of the overall model and simulation of the entire Clean Circles system

- Coupling of cost flows

- Define evaluation criteria for the technology (e.g. overall efficiency of electricity to electricity, exergy loss, retrofit options, etc.)