Probing the limits of metal strength

First-of-its-kind series of computer simulations focused on metal tantalum

2017/09/28

Researchers from TU Darmstadt and Lawrence Livermore National Laboratory in the U.S. have dived down to the atomic scale to resolve every “jiggle and wiggle” of atomic motion that underlies metal strength. Their research appeared in the Sept. 27 edition of “Nature” as an Advance Online Publication.

In a first-of-its-kind series of computer simulations focused on metal tantalum, the team predicted that, on reaching certain critical conditions of straining, metal plasticity (the ability to change shape under load) meets its limits. One limit is reached when crystal defects known as dislocations are no longer able to relieve mechanical loads, and another mechanism – twinning, or the sudden reorientation of the crystal lattice – is activated and takes over as the dominant mode of dynamic response.

Strength and plasticity properties of a metal are defined by dislocations, line defects in the crystal lattice whose motion causes material slippage along crystal planes. The theory of crystal dislocations was first advanced in the 1930s, and much research since has focused on dislocation interactions and their role in metal hardening, in which continued deformation increases the metal's strength (much like a blacksmith pounding on steel with a hammer). The same simulations strongly suggest that the metal cannot be strengthened forever.

“Ancient blacksmiths knew this intuitively”

“We predict that the crystal can reach an ultimate state in which it flows indefinitely after reaching its maximal strength,” said Dr. Alexander Stukowski, co-author of the paper from the Materials Science department in Darmstadt. “Ancient blacksmiths knew this intuitively because the main trick they used to strengthen their metal parts was to repeatedly hammer them from different sides, just like we do in our metal kneading simulation.”

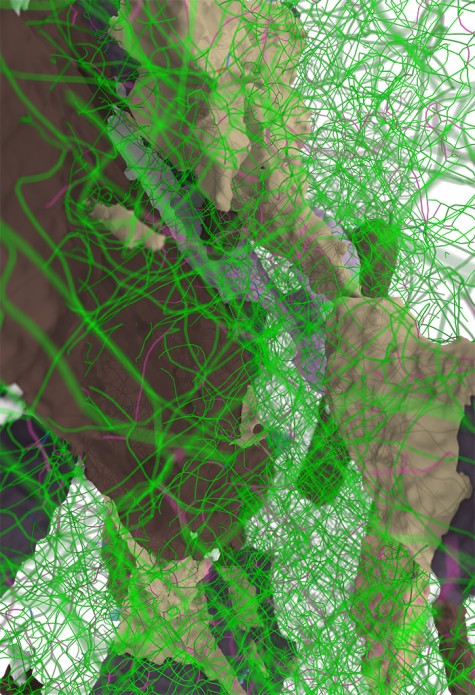

“We can see the crystal lattice in all details and how it changes through all stages in our metal strength simulations,” Dr. Stukowski said. “But even a trained eye is easily overwhelmed by the emerging complexity of metal microstructure and the immense number of atoms, which prompted us to develop precise computational methods to identify defects in the otherwise perfect crystal lattice and make them visible.”

The software OVITO and the advanced data analysis methods that helped the scientists reveal defect structures in the simulated metal are being developed by Dr. Stukowski’s research group at TU Darmstadt.

The team from Germany and the U.S. carried out the first fully dynamic atomistic simulations of plastic strength response of single crystal tantalum subjected to high-rate deformation. Unlike classical computational approaches to strength prediction, atomistic molecular dynamics simulations rely only on an interatomic interaction potential to resolve every “jiggle and wiggle” of atomic motion and reproduce material dynamics in full atomistic detail.

This new approach enables new detailed insights into the physics of metal plasticity, says Alexander Stukowski, and quotes the physicist Colin Humphreys: “Crystals are like people, it is the defects in them which tend to make them interesting.”

Publication:

Luis A. Zepeda-Ruiz, Alexander Stukowski, Tomas Oppelstrup, Vasily V. Bulatov: Probing the limits of metal plasticity with molecular dynamics simulations in Nature, 2017 (DOI: 10.1038/nature23472)

http://dx.doi.org/10.1038/nature23472

Software: http://www.ovito.org/