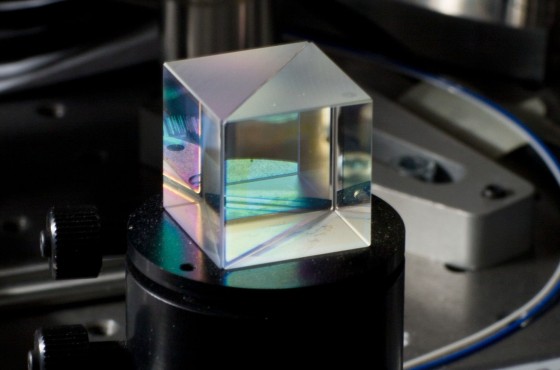

Bild: Katrin Binner

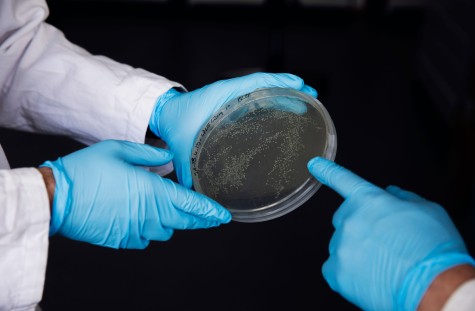

Bild: Katrin Binner

Forschungskooperationen und Auftragsforschung sind Formate der Forschung, in denen Wissenschaftler:innen der TU Darmstadt gemeinsam mit oder für Partner forschen. Diese dienen dazu, gemeinsam eine für alle Beteiligten interessante Fragestellung zu untersuchen. Alle Kooperationspartner beteiligen sich an in einem intensiven Austauschprozess. Im Rahmen von Auftragsforschung wird hingegen für einen Partner (als Auftraggeber) an der TU (als Auftragnehmerin) eine exakt definierte, in sich abgeschlossene Aufgabe bearbeitet.

Haben Sie Interesse an einer Forschungskooperation? Lassen Sie sich von unserem Portfolio in den xchange-Circles und in unseren Forschungsfeldern inspirieren oder kontaktieren unser xchange-Office.